Four Things to Consider Before Modernizing Your Manufacturing Facility

- April 23, 2020

- Best Practices

- Automation

Taking the “Tech” Out of Digital Transformation

Much is being said these days about digital transformation. The term itself sparks thoughts of bleeding-edge technologies and hyper-digital processes.

It’s true that digital transformation is changing the manufacturing industry by increasing flexibility, improving efficiencies and meeting customers’ changing needs. But digital transformation isn’t just about technology. It’s really about how you do your business.

Before technology can even be discussed, you should ask, answer and explore four key characteristics of your operation as a whole. Only then will you be truly prepared to successfully begin the process of a digital transformation.

Determine Key Objectives and Business Goals

Again, forget technology for a moment and consider what is holding back your operation from achieving your desired performance levels. For most manufacturers, workforce availability is the biggest obstacle here. But there are other factors in play too, including archaic facilities that need critical face lifts to attract better talent and boost workplace morale. Or maybe it’s a case of analysis paralysis – you might know what the problem is, but you’re overwhelmed by the number of different ways to fix it.

Technology will help your workforce by moving people to higher-value roles and leaving repetitive, mundane tasks to automation. It can help make your facility physically brighter, more vibrant and enticing for people to work. And, before you know it, you’ll be “detangling the technology” so you can actually move forward with solutions that make sense.

Don’t let obstacles derail you before you even begin the process of modernizing your facility. Once you have identified the challenges, you are in a much better position to choose solutions that will help you meet and exceed your business goals.

Assess and Prioritize

When you assess the effectiveness of your people, your operational processes, technology and the infrastructure associated with them, you can begin to prioritize the biggest needs for your facility.

Start by examining your current state. Think about the end-to-end process of an order coming into your company. How is it accepted? How does it make its way through your ERP system, to your production floor and ultimately to your loading dock? Are you fulfilling your customer’s order on or ahead of schedule… profitably? What are the interactions with various departments and systems? Look critically at each and every step in the end-to-end process, and prioritize the areas that need to be addressed first.

Without truly understanding these processes and how they interact, it will be extremely challenging to advance in the digital transformation maturity curve. And if you’re not making progress, most likely, your competitor sure is – and they may be producing more efficiently, more nimbly, and more profitably than you.

Engage Trusted Partners

Now that you’ve identified and prioritized your facility’s most pressing needs, it’s time to evaluate the appropriate available technologies and how to leverage them to your advantage. You understand what’s holding you back and where you want to focus your efforts . . . so which of your partners are key to helping you make progress?

Solid partners will already know what’s important to you for a successful outcome, and even what values are core to your company. They will push you to lock-in on the level of transformation that’s truly needed. They will help you apply technology to address those needs.

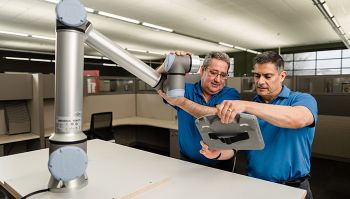

We’ve had traditional digital transformation solutions for decades, but in order to meet the needs of the market – with the #1 need right now being workforce ability – we’ve expanded our robotic line and introduced other services that can help customers address workforce challenges such as guided workforce solutions.

Trusted partners will ensure you’re applying the best technologies for whatever issues are impeding your ability to manufacture in the most productive way.

Consider Your ROI

Too often, digital transformation is viewed as yet another “thing” (i.e. a point solution) to be purchased in order to be digitally mature. This is akin to cyber security, in which companies invest in technology and change business processes to secure their data and networks. And yet, there isn’t one “thing” you can buy for a true and effective digital transformation.

It’s impossible to put together an accurate ROI when you’re looking at costs without really understanding the full financial benefits. This happens most when companies jump in to purchasing solutions before they fully understand their end-to-end process. And then they turn a problem into a larger one, not applying technology that ultimately improves their productivity.

Don’t panic! A trusted partner will stop you from biting off more than is necessary. And the steps above have enabled you to build an initiative or program that will move you to the next level. Now you can look at a realistic plan and associated ROI to strengthen your competitiveness, agility, enhance your market position, or meet any other metric that’s imperative to your success.

The biggest components of digital transformation are about processes, people, and systems. Before you decide to deploy technology, you must understand the fundamentals of how you do business. You have to know your foundational priorities. You need your partners to help you. Because it’s important that your teams accept and embrace the change that’s going on around them – not just what all of the changes and new technology is going in, but why it is being implemented. That’s where digital transformation begins.

JEFF SPADARO

EMPLOYEE-OWNER, VICE PRESIDENT OF AUTOMATION