Prepare for tomorrow by asking the right questions today.

Expert guidance throughout your industrial transformation process.

The first step in preparing for the future is understanding the challenges your business faces today. That’s why as we talk about industrial transformation or technology investments, we work to understand your business.

Then, we dive deeper, to understand how infrastructure, workflow and technology impact your ability to meet your goals. Based on your needs, we provide key assessments addressing operational efficiencies, current automation architecture and the critical network infrastructure that connects them. With our findings, you can confidently identify and prioritize areas where improvements can be made to prepare your business for the future.

What is the most critical step in your process to your profitability?

- What are your goals?

- What are your most important KPI's?

- How do you measure success?

- What challenges impact your goals?

Van Meter - Digital Transformation Brochure (PDF)

Operational Assessment

Is your work flow efficient from start to finish?

Between managing a workforce shortage, competing with businesses around the world and ever-changing customer demands, it’s more important than ever to be nimble and manufacture products quickly, accurately and profitably. That requires reviewing every system, process and person in the plant.

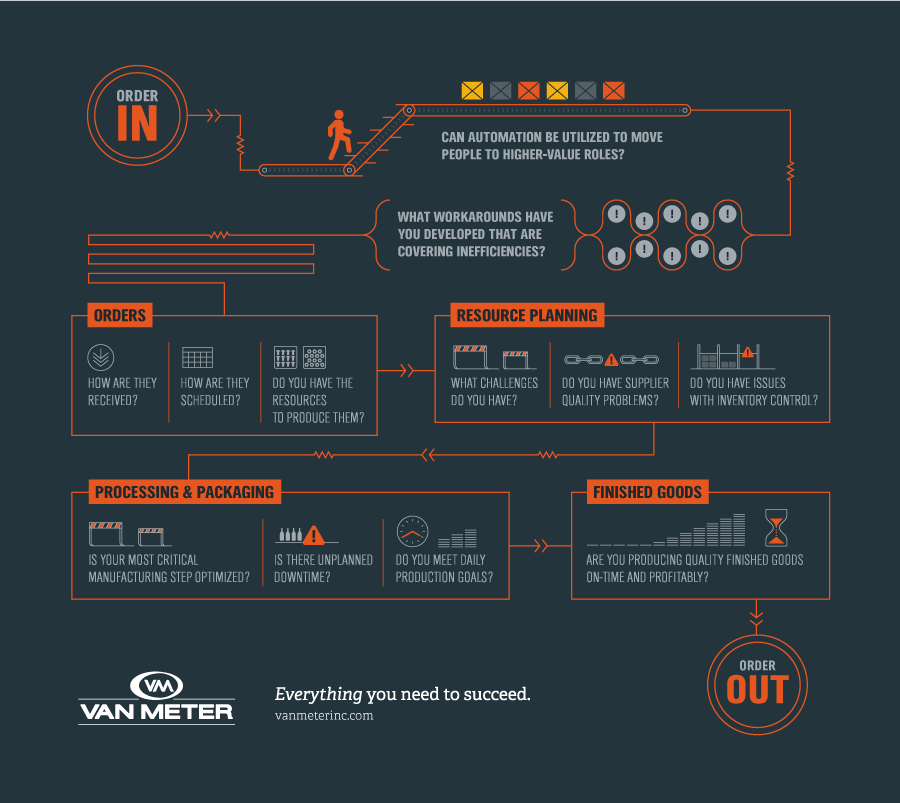

During the operational assessment we'll evaluate your process from order-in to order-out.

- Can automation be utilized to move people to higher-value roles?

- What workarounds have you developed that are covering inefficiencies?

- How are they received?

- How are they scheduled?

- Do you have the resources to produce them?

- What challenges do you have?

- Doyou have supplier quality problems?

- Do you have issues with inventory control?

- Is your most critical manufacturing step optmized?

- Is there unplanned downtime

- Do you meet daily production goals?

- Are you producing quality finished goods on-time and profitably?

We’ll work with you throughout the assessment to help you identify areas of improvement and recommend possible strategies to improve productivity and, ultimately — profitability.

Prepare for tomorrow by asking the right questions today. Get additional expert guidance throughout your industrial transformation process here: