Smart Sensors: Your Plant’s Eyes and Ears

- April 28, 2020

- Best Practices

- Automation

All manufacturing environments have an untapped resource at their fingertips. It transforms processes, streamlines go-to-market strategies, improves maintenance, boosts uptime, and ramps up yield. What is it? Data!

The amount of information that can be gathered and analyzed within an industrial environment is nearly endless. Most plants already use data for tracking purposes, but don’t use it to its full potential: to improve operations.

To take full advantage of the data your facility offers, you need to be able to capture this granular information. Deploying plug-and-play smart sensors supported by IO-Link open protocol can make this happen. By allowing a two-way data exchange from sensors and other devices, IO-Link technology can help industrial environments gather significantly more data, access numerous configurability options, and improve control to simplify installation, operations, and maintenance. (In other words: IO-Link technology is what makes sensors “smart.”)

Unlike traditional sensors that can only communicate one message – the presence of an object, for example – smart sensors collect many different data points (up to 32 bytes of data) about the application environment, reporting on factors such as temperature, humidity levels, speed, weight, airflow, sensor status, and more. Smart sensors can also receive data from the control system, allowing the altering of parameters, control of diagnostic LEDs, and turning sensors on and off.

They serve as your plant’s eyes and ears, reporting on what’s happening in real time with machines across the plant floor. They also monitor their own performance and condition, alerting you to potential issues right away so you can be proactive about sensor issues that could cause downtime or delays.

IO-Link masters serve as gateways by acting as PLC interfaces and controlling communication with connected devices. They link devices to other networks (like an EtherNet IP network) to share information with the control system.

Through access to Rockwell Automation’s Premier Integration experience, Van Meter simplifies automation system design, maintenance, and operations. All controller programming, device configuration, and maintenance management can be done through a single software. This makes integration faster and simpler, giving you easy access to the data you need to make better decisions.

Examples of Smart Sensors in Action

The data points captured by smart sensors can be used to automate plant processes, mistake-proof procedures, and continuously improve quality control.

A few examples:

- Smart sensors can accommodate repeated line changes (YouTube) – without requiring machine changeovers or manual adjustments. Once sensors are set up, they can receive information from controllers designed to store multiple profiles. With the press of a button, you can send a message to a specific group of sensors, telling them about a new color or size coming down the production line. Based on preset parameters, they can quickly and automatically adjust.

- Smart sensors can be programmed to send alerts when there’s an issue with their own performance, such as a dusty or damaged sensor (YouTube), so the impacted device can be identified right away. This helps you respond quickly to sensors that need cleaning or replacement to prevent unplanned downtime or backups.

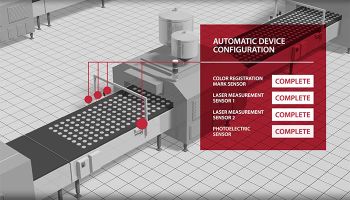

- Smart sensors can be set up to store their individual part numbers at the controller, allowing for easy replacement of damaged parts. The controller can also be set up to detect the newly installed smart sensor and automatically download required parameters.

How Van Meter Can Help

Van Meter’s automation team serves as a valuable resource for your plant environment and the data it produces, helping you decide how and when to deploy smart sensors enabled with IO-Link open protocol.

No matter how large your plant – or the processes you want to automate – we’ll help you figure out a cost-effective plan to improve operations by taking full advantage of the data your facility offers.