Massman's Collaborative Robots Offer New Packaging Solutions

- March 21, 2023

- Customer Success

- Automation

CLIENT: MASSMAN AUTOMATION | LOCATION: VILLARD, MN

Many of the largest product packaging facilities in the world rely on robotics solutions that are built in one of the smallest towns in Minnesota. From its small Villard, Minnesota, outpost, Massman Automation is doing big things in the packaging industry with the power of its Doosan collaborative robot solution.

THE CHALLENGE

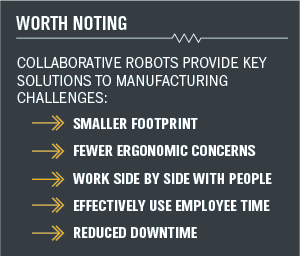

Mark Suchy, Senior Vice President of Sales and Marketing for Massman, sees collaborative robotics as a key solution to today’s manufacturing challenges.

“Everything’s footprint today,” said Suchy. “Footprint and having the people available. Right now, in our customers’ facilities, their operators are stretched very thin. They used to load the product, corrugate and materials separately and then palletize all in one. Now there’s more demand on them. There’s ergonomic challenges to palletizing cases all day. So now where a 10 to 15 per minute case palletizer may not have reached an ROI, today it does. And in order to service our customers, we need to be working on collaborative robotics.”

That’s where Van Meter’s expertise comes in.

THE SOLUTION

“Van Meter is always there to support us…and really just introduce us to the latest technologies,” Suchy said. “The Doosan robot, with the larger reach and the speed capabilities, and Van Meter’s support behind us was really what drove us into implementing this solution.”

Unlike traditional robotics, collaborative robotics is a system that can operate and interact in the same workspace as an operator. “In traditional robotics,” explained Suchy, “the robots operate within a fenced area, which naturally takes up more distance.”

“These [Doosan] robots are allowed to work with human interaction with no safety required,” added Van Meter Solution Consultant, Zach Dotson. “They have internal safety and torque sensors so you can work…without having to be worried about safety zones.”

To put it even more plainly, the Doosan robot will stop as soon as it comes into contact with a person or object, functioning as a safe system that takes up less footprint in a manufacturing facility and puts less demand on the body of an operator.

“To operate in an area with operators hand in hand, side by side, this is the perfect solution,” Suchy added.

THE RESULT

It’s an affordable solution too with most models ranging anywhere from $30,000-$70,000. That makes for a quick payback for Massman’s industry-leading food customers.

Typically a collaborative robot will have a return on investment in the period of three to six months.

“The big benefit with robotics over human labor is you don’t have breaks, you don’t have downtime, you don’t have sick days; you hit the button and the robot runs,” Dotson added.

This doesn’t mean that collaborative robots are replacing employees. In most cases, they’re making their jobs safer and easier.

“So if you think about palletizing applications,” explained Dotson, “where a person is constantly bending over, picking up a case, turning, setting it down, that can cause a lot of strain on your back and muscles…, a lot of fatigue, a lot of workplace injuries. The robots help solve that…along with this, you’re not eliminating that person, you’re allowing them to use their time elsewhere so they can tend to other components of the machine or the line or the process that maybe can’t be automated or have to be done manually with human interaction. So you’re not losing an employee, you’re just moving them to somewhere where they’re more valuable.”

“Right now, in our customer’s facilities, their operators are stretched very thin…And in order to service our customers, we need to be working on collaborative robotics.”

- Mark Suchy, Massman Companies

YOUR AUTOMATION SOLUTION

Van Meter Inc. provides expert advice in the selection and design of automation solutions and more. We welcome your call to discuss your next project. To speak with a Van Meter representative, call 1-800-247-1410. We’ll quickly connect you with the person or information you need.