Five Reasons to Upgrade To The Powerflex 755TS Smart VFD

- October 7, 2025

- Video

- Automation

Are you looking to get more insights from your motor control system, reduce mechanical wear on your system and better schedule maintenance on your drives and system? It’s all possible when you upgrade to the 755TS variable frequency drive (VFD) from Rockwell Automation. With predictive analytics, better precision, and more flexibility, the 755TS is a smart VFD that can upgrade your motor control system. Learn from our power control specialist, Griffen Clark, about the 755TS in the video below or check out these five reasons to upgrade to the 755TS.

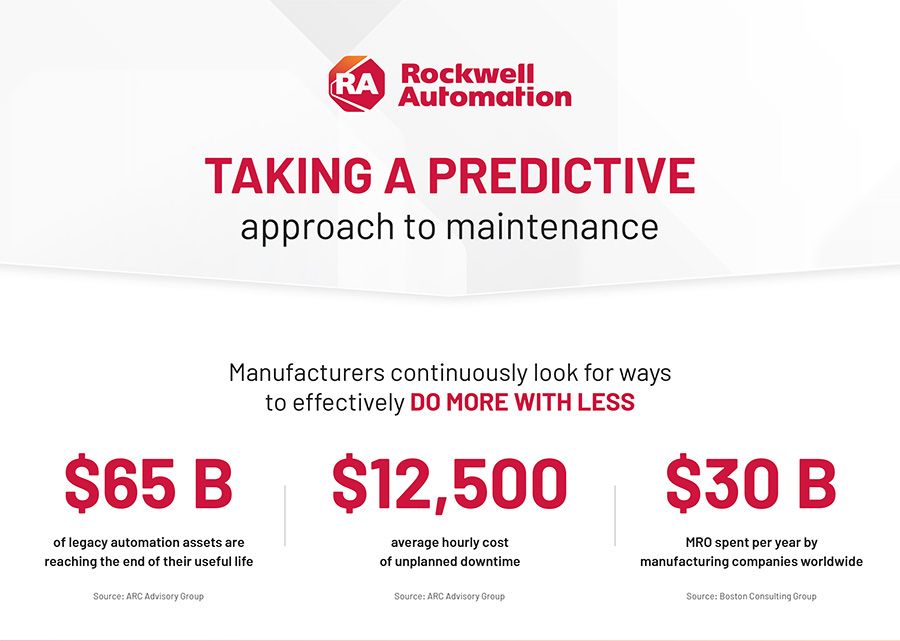

1. PREDICTIVE MAINTENANCE ANALYTICS REDUCE UNPLANNED DOWNTIME

Unplanned downtime is costly and makes it difficult to reach your production potential. The PowerFlex 755TS provides predictive maintenance analytics, so you can schedule maintenance around your planned shutdowns instead of part breakdowns.

For example, the drive can monitor heatsink temperature or capacitor life and alert you when parts are getting worn down. Think of how your car tells you it needs an oil change. Instead of waiting for a fan to stop spinning or the drive to overheat, you can see when a fan has 10% of its life left and plan ahead to replace it. More informed maintenance planning leads to more uptime and more production from your system.

2. BETTER PRECISION IMPROVES MOTOR CONTROL

Another way to increase production is more precise motor control. Whether you are simply spinning a motor or working with specialized applications that require high-performance motor control, the 755TS is up to the task. The 755TS is the most precise VFD Rockwell offers and flexible enough to be applied to nearly any industrial application. With higher control bandwidth, improved torque accuracy and superior velocity tracking, the 755TS is an improvement over PowerFlex 700S or standard PowerFlex 755 drives.

3. ADAPTABILITY REDUCES MECHANICAL WEAR ON YOUR SYSTEM

Drive outputs can negatively affect the reliability of mechanical systems. That’s why the PowerFlex 755TS has real time operational intelligence and adaptive tuning that adjusts the drive to your system.

The 755TS can adapt to changing conditions and automatically adjust output as needed to best run your motor. It also automatically suppresses potentially harmful resonance and vibration conditions. That means your operation will be more concise and controlled without having any user interface, and you are increasing the lifespan of your equipment.

Predict Problems Before They Happen

PowerFlex® 755T drives with TotalFORCE® technology give you real-time insights into equipment health—helping you reduce downtime, extend asset life, and make smarter maintenance decisions.

4. BETTER DURABILITY AND SECURITY IMPROVE VFD RELIABILITY

In addition to reducing wear on your equipment, the drive itself can withstand harsh environments and protect against cybersecurity threats. Compared to a standard 755 drive, the 755TS provides better environmental protection with optional XT corrosive gas protection that can withstand the harshest industrial environments.

As new devices go online in your plant, cybersecurity threats are another risk to your production and can lead to unplanned downtime. The 755TS supports Common Industrial Protocol (CIP) security that ensures privacy between your devices. CIP security is part of a defense in depth strategy that makes products and systems more secure. With resistance to environmental and cybersecurity risks, the 755TS is best in class for consistent production and reliability.

5. UPGRADING TO THE 755TS IS CONVENIENT

Transitioning to new drive technology doesn’t have to mean redesigning your entire install. The PowerFlex 755TS shares the same physical dimensions and mounting bolt patterns as the standard PowerFlex 755, making installation straightforward. Existing option cards are also compatible, allowing you to streamline the upgrade process.

Are you ready to try the PowerFlex 755TS for yourself? Do you want to see how it works? Contact your Van Meter account manager to learn more or see a demo.

ARTICLE BY:

GRIFFEN CLARK

EMPLOYEE-OWNER, POWER CONTROL SPECIALIST