5 Signs It’s Time to Invest in Autonomous Mobile Robots (AMRs) For Your Facility

- January 29, 2026

- Best Practices

- Automation

Autonomous mobile robots (AMRs) are self‑navigating transport robots equipped with sensors, intelligent software and obstacle‑avoidance technology that move materials safely and efficiently across industrial environments.

Do you know why Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are a top investment for manufacturers in Rockwell Automation’s latest State of Smart Manufacturing Report? Could you benefit from implementing AMRs? See if you recognize these signs of when it’s time to invest in autonomous mobile robots.

Modern autonomous mobile robots improve productivity, enhance worker safety, increase flexibility compared to AGVs, and optimize plant intralogistics.

OTTO 1500 AMR moving a heavy load on the plant floor, showcasing safe, consistent, 24/7 material flow.

1. YOUR THROUGHPUT CAN’T MEET DEMAND WITHOUT AUTONOMOUS MOBILE ROBOTS

How do manufacturers reach growing production goals with fewer resources during workforce shortages? Material handling accounts for 25% of the manufacturing workforce on average. Manufacturers don’t need as many people to quickly and safely move materials through their facility when they utilize autonomous mobile robots.

While a leisurely walking pace is roughly 2 mph, autonomous mobile robots, including tugger, platform, and stacker AMR types, can lift and transport payloads at speeds up to two meters per second. That equals 4.5 mph.

In addition to being twice as fast, industrial robots don’t get tired or injured and don’t need breaks as often. Some AMRs can work an entire eight-hour shift or longer without charging. When deploying two or more AMRs for a task, manufacturers can continuously have at least one AMR running while the other charges.

Mid‑capacity OTTO 1200 keeps materials moving between workcells, helping teams hit production targets.

2. WORKFORCE RETENTION CHALLENGES SIGNAL IT’S TIME FOR AMRS

Carrying heavy materials across long distances all day is a difficult task that can cause injuries and frustrate workers.

Many manufacturers are having a hard time finding and keeping qualified workers. Autonomous mobile robots help by taking over tasks like lifting and moving products in the warehouse. This allows workers to shift into higher‑value, skill‑based roles that contribute more directly to production efficiency.

Manufacturers will be better positioned to retain talented workers when they can offer more fulfilling roles.

Compact OTTO 100 takes on repetitive transport tasks, freeing your team to focus on higher‑value work.

3. HIGH TURNOVER AND SKILLS GAPS INCREASE THE NEED FOR AUTONOMOUS MOBILE ROBOTS

What can manufacturers do to replace knowledge and experience when workers leave? High turnover creates costly skills gaps that can jeopardize safety and productivity.

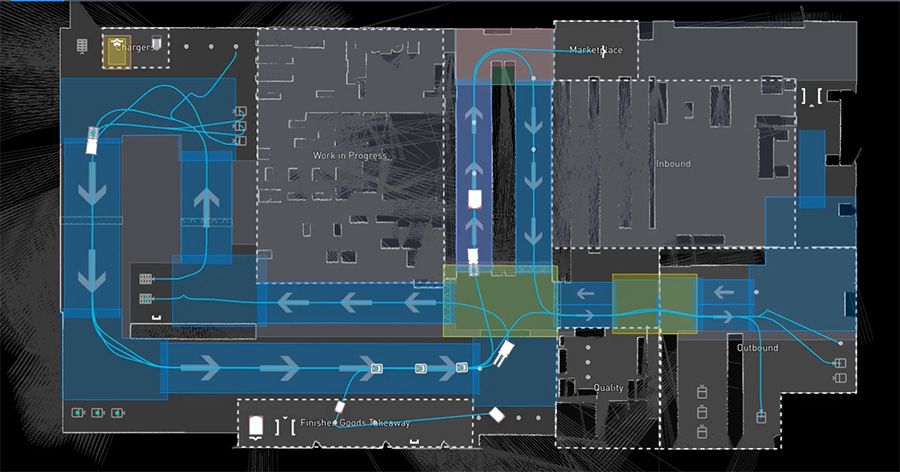

Fleet Manager maps routes, optimizes traffic, and standardizes best practices.

Manufacturers can pre-program autonomous mobile robots with a map of the plant layout and optimum routes between locations. The robot will then know how to navigate the plant floor along the most efficient path.

AMRs equipped with SLAM and AI‑driven navigation continuously learn facility layouts, detect obstructions, and autonomously reroute along the most efficient paths. Over time, they even learn how to avoid recurring obstructions.

Investing in autonomous mobile robots is often more efficient than continuously investing resources in recruiting and training new workers.

Why OTTO AMRs Stand Out

Explore how OTTO autonomous mobile robots deliver advanced navigation, fleet intelligence, and proven reliability in industrial environments.

4. REDUCING SAFETY RISKS WITH AUTONOMOUS MOBILE ROBOTS

New employees take time to learn safety procedures and adopt new equipment. Even if they do follow safety procedures, humans operating forklifts and interacting with machinery increase the risk of injury.

Repeatedly lifting and transporting heavy items puts unnecessary stress on workers and can lead to injury. Autonomous mobile robots reduce the risk of injury by distancing humans from the process. They utilize multilayer safety systems, including lidar, 2D and 3D obstacle detection, and safety‑rated controllers, to meet industrial safety standards.

Using technology that has been safety tested and certified is often safer than counting on inexperienced or fatigued workers.

5. AMRS HELP MAXIMIZE FLOOR SPACE AND INTRALOGISTICS EFFICIENCY

Investing in real estate is not always the best solution when factory floor space is tight. Autonomous mobile robots help manufacturers increase production within the floor space they already have.

AMRs enable more flexible intralogistics layouts, allowing engineers to redesign production flows and machine interfaces without fixed infrastructure constraints. They have more flexibility designing machines if the machine is interacting with an AMR instead of a human. AMRs condense machine size and save space without sacrificing production because they are not fixed in place.

Small footprint, big impact - AMRs fit tight layouts and keep intralogistics flowing without fixed infrastructure.

AMRS VS. AGVS: WHY AUTONOMOUS MOBILE ROBOTS OFFER MORE FLEXIBILITY

Unlike AGVs that follow fixed routes guided by wires, magnets, or reflectors, AMRs use mapped environments and onboard sensors to plan paths dynamically. This flexibility reduces reconfiguration costs and accelerates deployment when layouts change

SEE AUTONOMOUS MOBILE ROBOTS IN ACTION: HOW AMRS TRANSFORM MANUFACTURING AND INTRALOGISTICS

Are you ready to see one of these autonomous mobile robots for yourself? Schedule an autonomous mobile robot demo to explore AMR applications in material transport, intralogistics, and production workflows. Van Meter’s robotics service team are ready to discuss possible applications in your facility.

SCHEDULE AN AMR DEMO

Ready to explore how autonomous mobile robots can optimize your material flow, reduce labor strain, and modernize your intralogistics operations? Fill out the form below to schedule an AMR demo with Van Meter’s robotics experts.

About the Author:

GEORGE ROVOLIS

Smart Machines & Robotics Business Manager, Van Meter Inc.