Achieve 20/20 Quality Vision with Rockwell Automation’s VisionAI

- May 1, 2025

- Best Practices

- Automation

If you’ve ever glanced through a “Where’s Waldo” or “I Spy” book, you know that spotting something that doesn’t belong can be difficult. Imagine trying to detect anomalies in high speed, highly variable manufacturing processes with sufficient reliability. It’s a nearly impossible task.

Now imagine training your team members to perform this task. Even if they had 10 seconds to make the visual inspection, will they catch everything?

The good news for manufacturers is there is a quicker, more reliable, automated method of quality inspection. Get to know these benefits of Rockwell Automation’s quality inspection platform, FactoryTalk Analytics VisionAI, to learn how it can help you improve quality management.

ADVANCED ANOMALY DETECTION

Having someone manually inspect processes is error-prone and tedious. It requires a lot of training to do it right, and with a constant churn of frontline team members doing quality inspections, quality issues can slip through the cracks.

Manufacturers can automate quality checks with sensors or a Zebra machine vision solution for applications without much variance in SKUs. For applications with more variability, using VisionAI alongside your machine vision solution can make quality inspections more efficient.

Think about a product that has a thousand options. Measuring quality isn’t always black and white, so if you don’t have the right algorithm to classify the variations of what is good and what is bad, training a person or a vision system to recognize quality errors on a thousand different configurations is extremely time consuming. There can be many variations of ‘good enough’ or ‘not up to standard,’ and VisionAI can differentiate between the good, the bad and the ugly.

VisionAI uses AI algorithms to classify issues. When you label images as good, bad or borderline, it categorizes similar images together using Smart Group or Prediction(s). The Smart Group tool uses unsupervised learning to try and group together images that look the same. Once the images are grouped, a quality technician can analyze the entire group of images at one time. The Prediction tool groups unlabeled images by the label that Vision AI predicts the model would apply. It can turn sorting through thousands of pictures into a couple of clicks.

How accurately does the AI group images? It will tell you! VisionAI provides a training report that shows the accuracy of the model, the false defect rate, the defect escape rate (images with defects it doesn’t catch) and the number of images used to build the model.

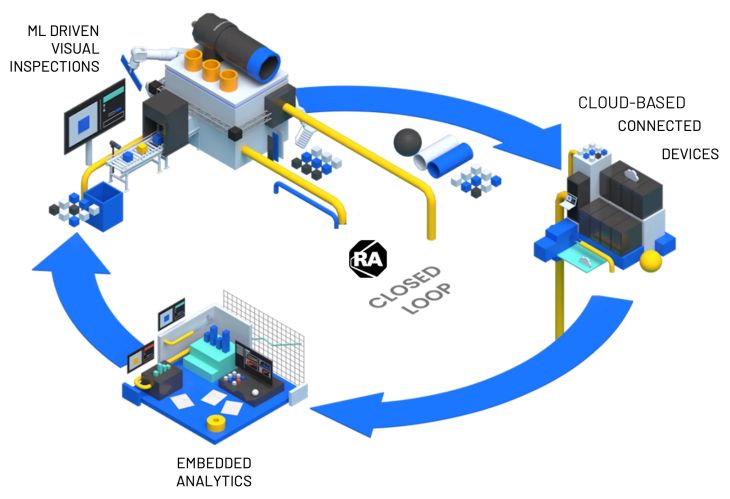

CLOSED LOOP QUALITY

Once it’s initially trained, VisionAI continues to learn and evolve as it is running. As you have new inspections that are borderline or poor quality, the algorithm constantly updates so it can make more accurate judgements in the future.

VisionAI runs right at the production line, but it also has a closed-loop circuit connection. Why is that a big deal? Enterprise customers in Rockwell Automation’s 2023 State of Smart Manufacturing Report said closed-loop quality was rated the number one impact area for AI in manufacturing.

Here’s how it works. As your vision system makes quality inspections, the data from those inspections goes up to the cloud and trains the AI algorithm. The newly refined algorithm then gets pushed back down to the production line to continuously improve decision making on product quality.

Closed-loop quality was rated the number one impact area for AI in manufacturing (State of Smart Manufacturing, 2023).

The continuous improvement from Vision AI isn’t just contained to the production line or facility it’s collecting data from. Vision AI is browser based, so anybody with the proper security credentials can look at it from anywhere in the organization. That means a subject matter expert in one location can train multiple production lines thousands of miles away.

Without the cloud, they would have to remotely connect into each of those systems. With VisionAI’s end-to-end workflow, they can easily deploy shared machine learning models across their manufacturing facilities. Instead of training one production line at a time, all their production lines can learn from each other.

ROOT CAUSE ANALYSIS

With built-in quality data analysis, pre-built dashboards, automated reporting and quality event notifications, VisionAI doesn’t just tell you whether you have quality issues. It can help you understand why you have quality issues. Users can view all the failed images at a glance and double click into images to learn about which tool failed and why. Plus, they can see quality data like fail rate and most common defects. They can then utilize the quality data to analyze whether there is an issue with the production asset and make operational improvements to optimize quality in the future.

State of Smart Manufacturing Report

Download the report now to find out what’s working for leading manufacturers, benchmark your technology usage, explore best practices and uncover 2024 trends.

DOWNLOAD REPORTROCKWELL AUTOMATION INTEGRATION

If you’re already using Rockwell Automation hardware and software solutions in your automation system, implementing a machine vision solution with VisionAI is simple. Zebra machine vision and VisionAI both integrate with Rockwell Automation’s Logix controllers. For example, as soon as your vision system recognizes what it would classify as scrap material, it can automatically kick that product off the production line. It can do it quickly too. VisionAI can provide real-time inspections at production speeds, as it can run at up to 450 units per minute. VisionAI is available via FactoryTalk Hub, Rockwell Automation’s cloud-based platform for applications. It does not require any coding to use, and with a common user interface, it makes it easy for subject matter experts to use.

CYBERSECURITY

While some AI programs can add cybersecurity risks, your data is secure with VisionAI. What makes it safer? With a closed-loop circuit connection, the AI is only trained on your data and not influenced by information from outside the organization. Plus, VisionAI’s network security is SOC 2 Type 2 compliant, which is the same compliance standard as well-known cloud platforms like Dropbox, Amazon Web Services, GitHub and more.

SEE IF VISIONAI IS A GOOD FIT FOR YOU

Do you have an application that could benefit from Zebra machine vision and Vision AI? Van Meter has trained specialists who can analyze machine vision use cases in our lab to see if it’s a good fit. Reach out to your Van Meter account manager or contact us in the form below to work with a specialist.

ARTICLE BY:

KARL SCHMIDT

EMPLOYEE-OWNER, SOLUTION ARCHITECT