Choose The Right Type Of Industrial Robot For Your Operation

- October 1, 2024

- Best Practices

- Automation

Speed date each type of industrial robot to meet your perfect match 💞

Industrial robots solve challenges for manufacturers—like productivity, safety, maintenance and workforce challenges—and work well for jobs that are dull, dirty, dangerous and/or difficult. But how do you know what type of robot is right for your application? What tasks can each type of industrial robots perform? To help you find your perfect match, let’s get to know some types of industrial robots and how you can deploy them to boost productivity.

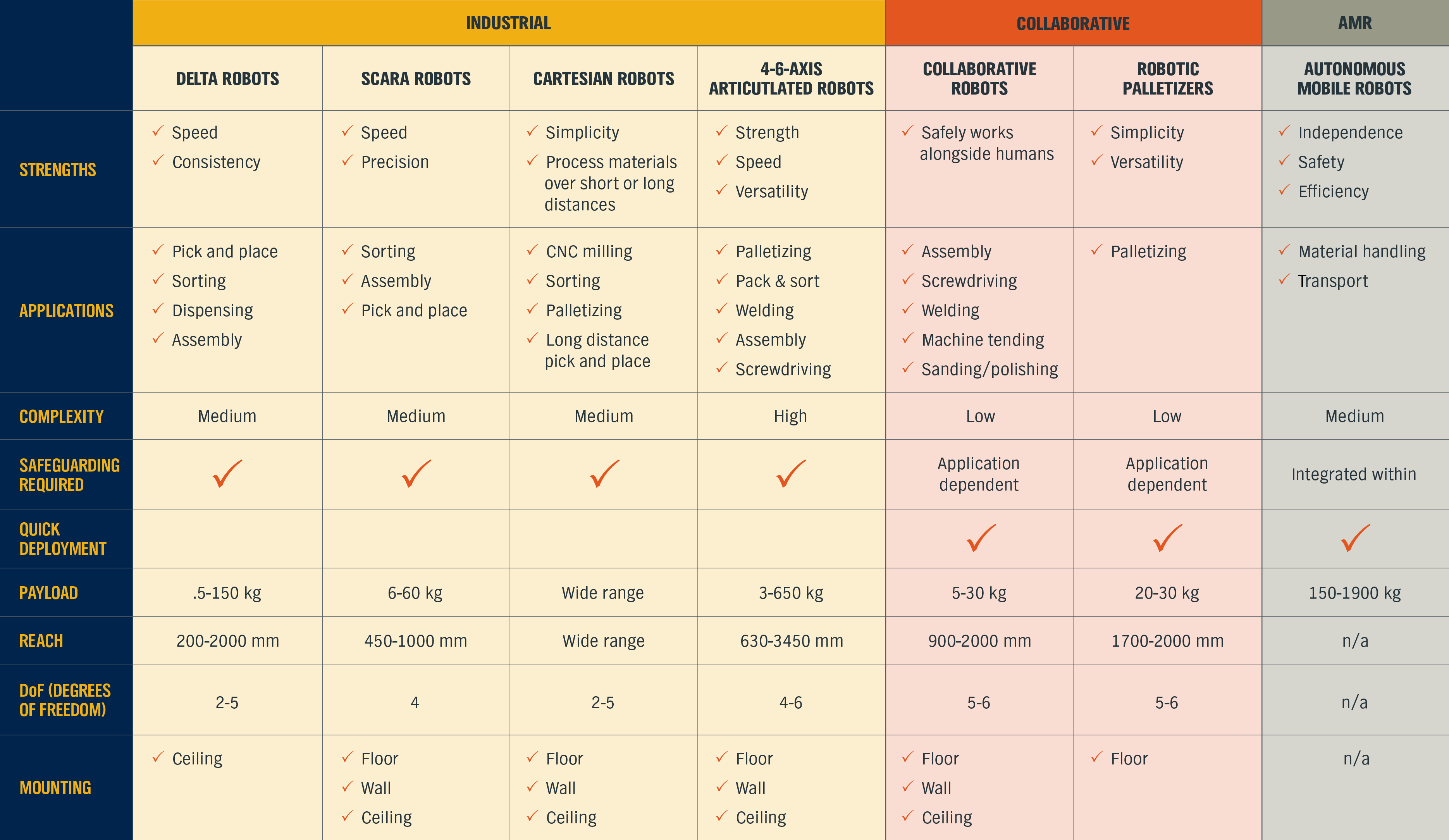

COMPARE TYPES OF ROBOTS AT A GLANCE

ROBOT #1: DELTA ROBOT

Moves Fast

If you want things to move quickly, you should get familiar with delta robots. Delta, or “Spider,” robots are designed with all arms connected to a universal base (resembling a spider). Because the motors are in the stationary base and not the robot arms, delta robots can move more quickly and are perfect for high-speed applications. They can process up to 300 parts per minute.

Think of an application where items are coming down a conveyor and need to be placed into a bin. Delta robots can pick and place those items more quickly and accurately than humans, and it frees your people up to work on something more impactful. Delta robots can only handle smaller payloads and have a limited work envelope (or area of space it can reach), so it’s best to use delta robots for pick and place, sorting, dispensing, assembly and small-scale machining applications where speed is important.

ROBOT #2: SELECTIVE COMPLIANCE ARTICULATED ROBOT ARM (SCARA ROBOT)

Ensures Quality Time

If you’re working in a more intimate space, the SCARA robot only requires a small footprint, but it is mighty productive for high-speed and high-accuracy applications. SCARA robots are versatile, as they can be mounted on the ceiling, wall or machine they are working on and have four axes of movement. They are not as fast as delta robots, but they are more accurate and for many applications, more cost effective.

A SCARA robot can only manage smaller payloads (less than ~13lbs) and has a smaller work envelope, but its repetitive pinpoint precision reduces production errors to solve quality concerns. Use a SCARA robot to sort, assemble or pick and place products.

ROBOT #3: CARTESIAN ROBOT

Loves to Travel

If you’re more interested in an industrial robot that thrives over long distance, cartesian robots are mounted from above and great for moving a wide variety of payloads over large distances. They can move in a straight line up, down or sideways and can be built to a specific length. If you need to move a payload 20 feet down a line, you can build a 20-foot section for the robot to slide across. They can also be outfitted with a variety of arms and grippers to manipulate and transport products. Cartesian robots are best used for CNC milling, sorting, palletizing or picking and placing items over long distances.

ROBOT #4: SIX-AXIS ARTICULATED ROBOT

Strong, Flexible and Active

Is your perfect match the type of industrial robot that you can do a lot of different activities with? Six-axis robots are the best option for performing a large variety of functions that require a wide range of motion. As the name implies, they have six axes of movement, and they can handle payloads from a few kilograms to a thousand kilograms. Think of an articulated robot as a human arm but stronger, as it can be equipped with different grippers and accessories to manipulate products in different ways.

Six-axis robots are great for palletizing and stack and sort applications, as they can lift and place heavy objects where they need to go. They can even be used for welding or painting. Because a six-axis robot has more joints and rotating parts, it will not operate as quickly as a SCARA robot or delta robot, but its versatility is unmatched.

ROBOT #5: COLLABORATIVE ROBOT (COBOTS)

The Ideal Partner

Not all types of industrial robots replace human workers. You can safely deploy cobots on their own or right next to human workers to improve quality, consistency and safety. Cobots also have six axes of movement and can do many of the same activities as six-axis articulated robots, but they move slower and can safely work around people.

Collaborative robots are safe to work next to because they can stop performing a function faster than humans can. The slightest bump (down to 0.2 Newtons of force) will shut down a cobot before it can harm anyone in its path of motion. Cobots offer flexibility and versatility, as you can quickly and easily move, reprogram and redeploy them for different tasks. Use cobots for applications like assembly, screwdriving, welding, etc.

ROBOT #6: ROBOTIC PALLETIZERS

Does the Heavy Lifting

The ideal robot should make life easier, right? If you want to automate monotonous, strenuous tasks – like palletizing – you should see how easy it is to implement a robotic palletizer. With the right robotic palletizer , you can set it up and start palletizing in five minutes.

Palletizing systems can come with the conveyor, scanners, controller and software pre-programmed from the factory and ready to use. If you’re using a collaborative robotic palletizer , it doesn’t have to be guarded for safety, and it can be wheeled around the plant and redeployed for various tasks.

The repetitive nature of hand palletizing requires constant twisting, bending and lifting that heightens the risk of injury for your workforce. With a robotic palletizer, you can redeploy those people to perform safer, more fulfilling roles in your operation.

ROBOT #7: AUTONOMOUS MOBILE ROBOTS (AMRs)

Independent and On the Move

For some people, the perfect type of robot is one that can work independently without supervision. Autonomous mobile robots can independently, safely and efficiently navigate their environment and transport materials across large areas – in some cases, more safely and efficiently than humans. With an estimated 2.1 million unfilled U.S. manufacturing jobs by 2030, manufacturers can use AMRs to fill in gaps when it’s hard to find workers.

AMRs can handle materials from a couple hundred to 4000+ pounds, so they are perfect for small or large material handling jobs on your factory floor, like identifying, grabbing and transporting materials across your plant floor while safely avoiding obstacles and people.

SEE YOUR FAVORITE TYPE OF INDUSTRIAL ROBOT IN ACTION

Do any of these industrial robots sound like your perfect match? Want to see one or a few of them in action (don’t worry, robots don’t get jealous)? Connect with one of our industrial robotics experts to schedule a demo and learn how these industrial robots will improve your productivity, quality and safety.

ARTICLE BY:

NOLAN MILLER

EMPLOYEE-OWNER, MECHATRONICS SPECIALIST

Click here to enlarge »

Click here to enlarge »